Need an Intelligent RF Diagnostic Tool? NeoScan is the Solution

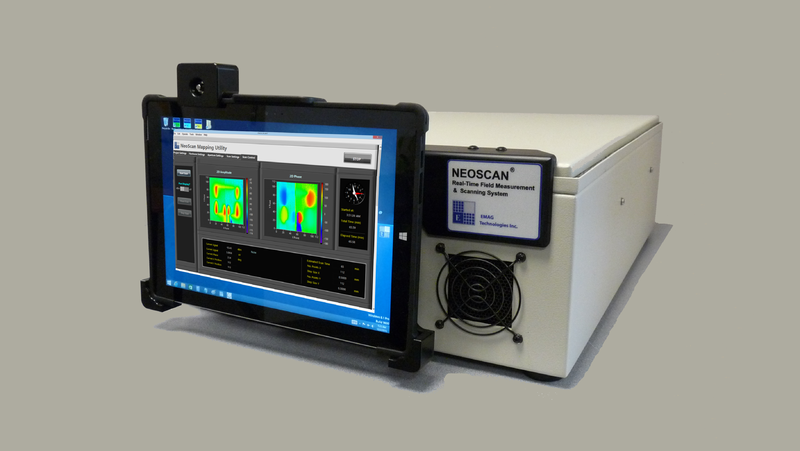

Breakthrough Turnkey Field Measurement System

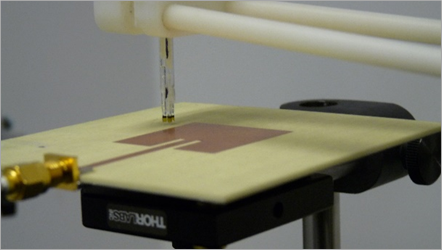

NeoScan® is a unique electric field measurement system with unprecedented innovative features. NeoScan systems utilize EMAG’s patented, electro-optic (EO) field probe technology. Unlike conventional near-field scanning systems that require metallic pickup radiators or sensors, NeoScan probes are made of absolutely metal-free parts. Our field probes feature miniaturized optical crystal tips mounted on optical fibers. The combination of extremely small probe footprint and absence of metallic parts or interconnects at the signal pickup area warrant the ultimate RF non-invasiveness. Because of their optical nature, NeoScan probes provide an ultra-wideband measurement capability and a very high spatial resolution that is essentially limited by the laser beam spot size.

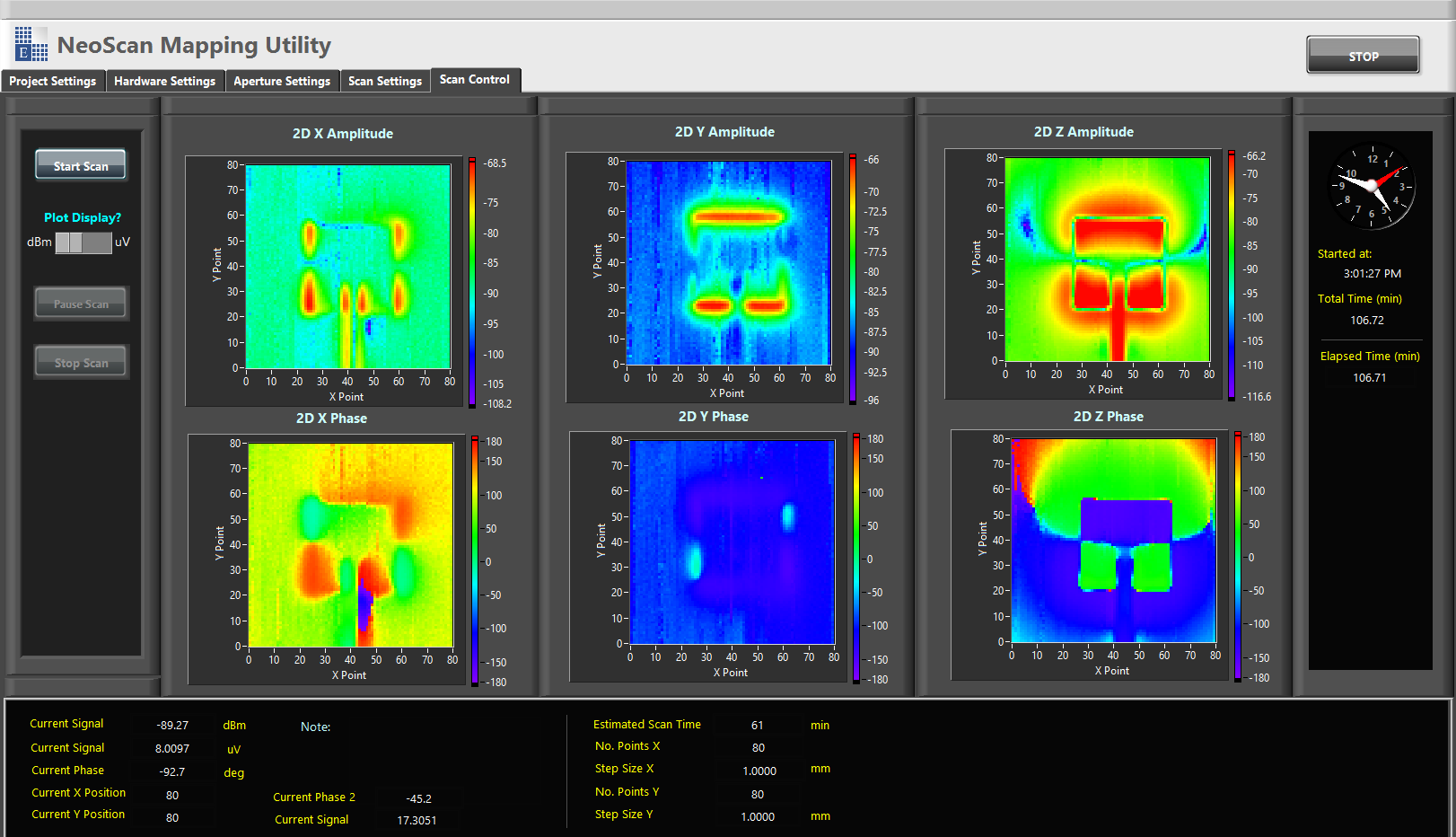

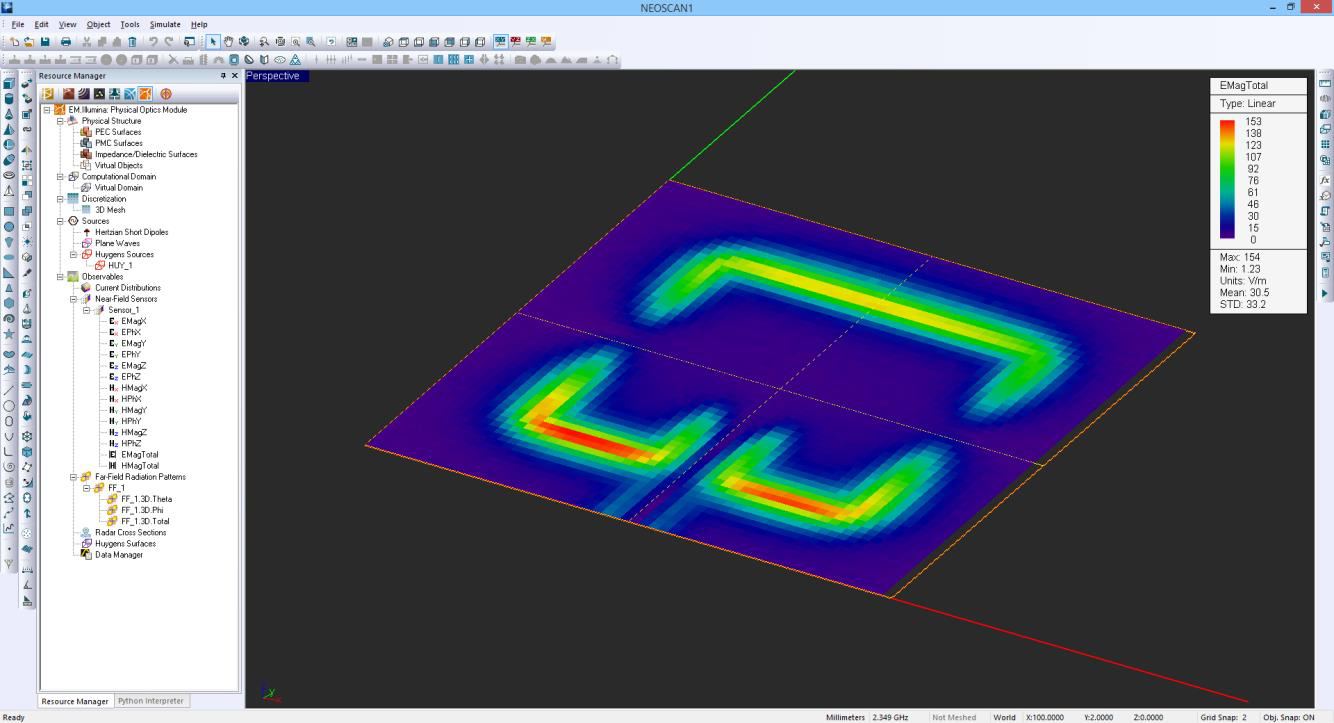

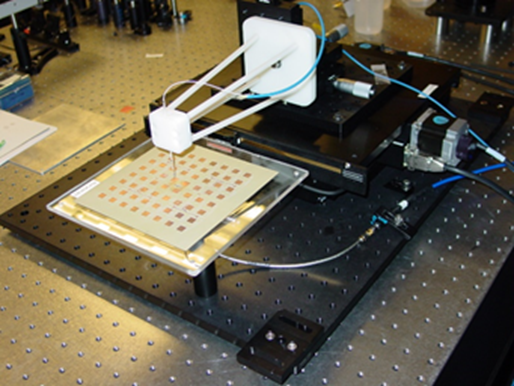

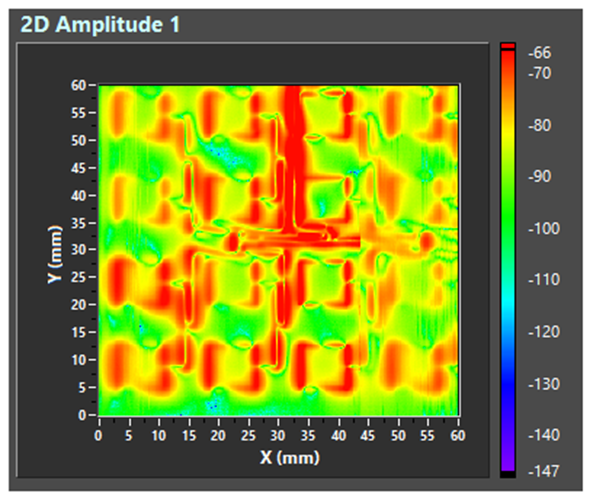

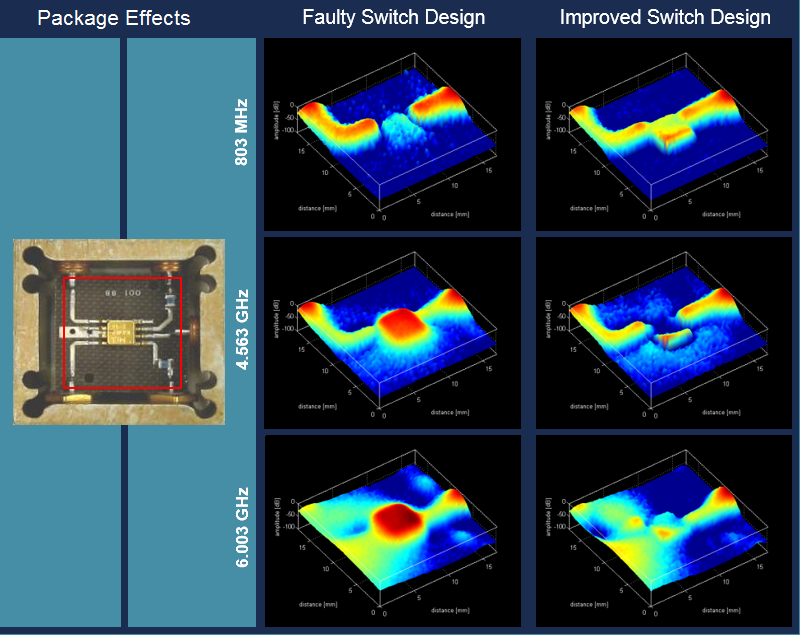

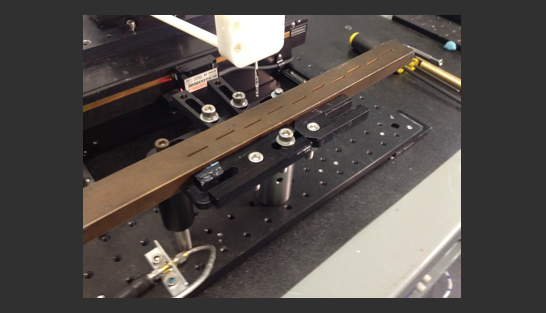

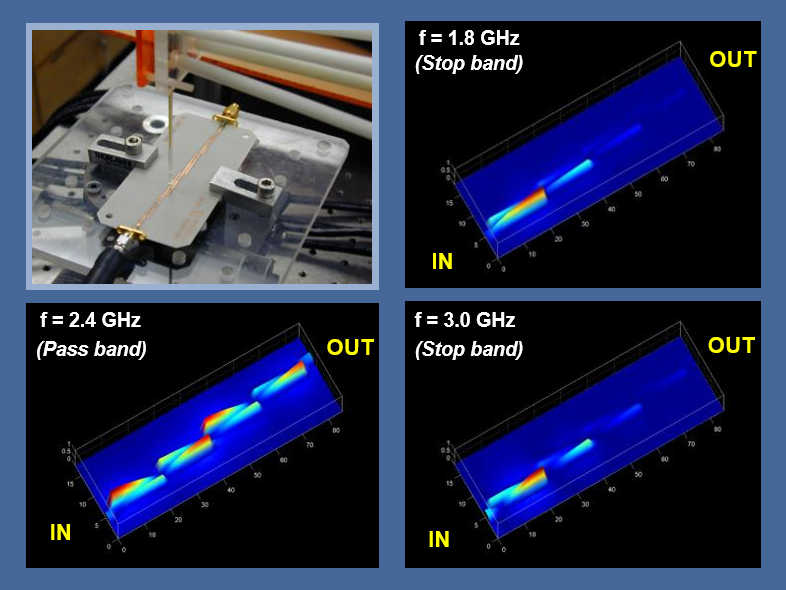

You can use the NeoScan system to detect or monitor electric fields over time at fixed points around your circuit or device. Since NeoScan probes are non-contact and virtually exhibit an infinite impedance, they can be effectively used for tracking transient waveforms in real time. When the probe is mounted on a precision translation stage, using a CW signal generator, NeoScan can also provide detailed field maps of passive and active devices and circuits including radio frequency integrated circuits (RFICs) and monolithic microwave integrated circuits (MMICs). Such insightful information can be used for design verification, model validation, fault isolation or performance evaluation of various parts of your RF system.

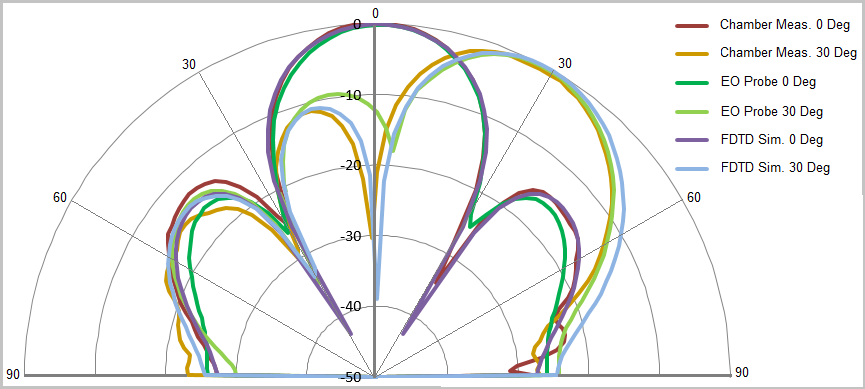

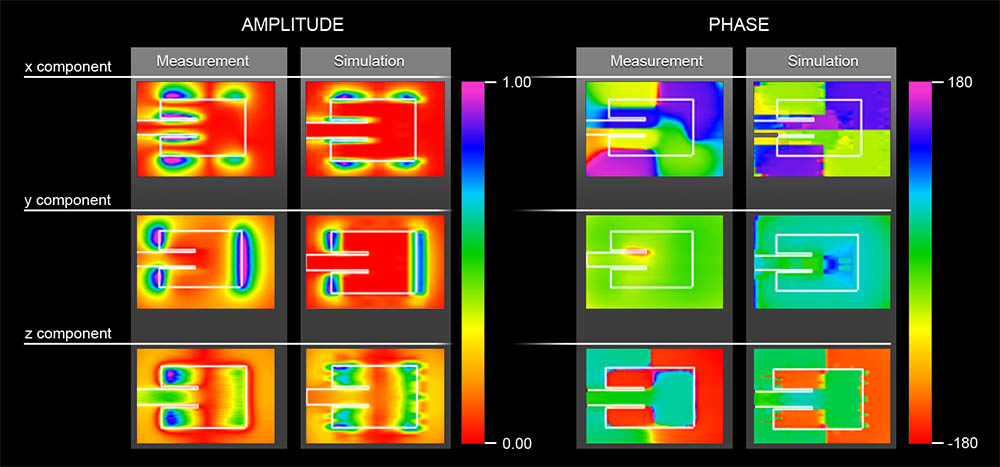

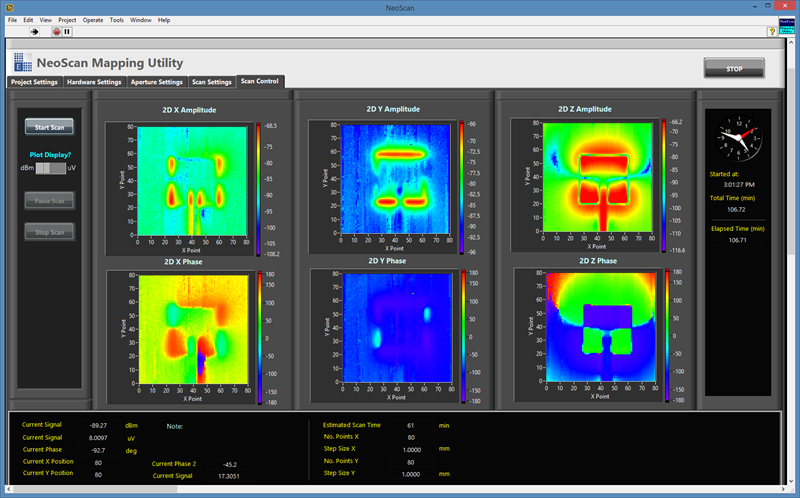

NeoScan measures the amplitude and phase of the electric field simultaneously. Using both tangential and normal EO probes, all the three vectorial field components can be measured accurately with a good level of polarization discrimination. In a near-field scanning configuration, NeoScan can produce coherent, polarimetric, aperture-level field distribution maps with minimal invasiveness to the antenna under test. From these maps, NeoScan estimates the 3D far-field radiation pattern of the antenna under test without requiring a large and costly anechoic chamber installation.

Unique RF Test & Characterization Capabilities

Some of the key features of NeoScan field measurement systems include:

- Non-intrusive and non-contact RF measurement

- Broad measurement bandwidth (10MHz – 40GHz) using the same optical probes (lower and higher operational bandwidths available as custom configurations)

- Simultaneous amplitude and phase measurement

- Vectorial component measurement with cross polarization suppression better than 20dB

- Very wide dynamic range (>70dB) measuring very low field intensities under 1V/m to extremely high field intensities above 2MV/m using the same optical probes

- Typical probe tip size: 1mm3

- High spatial resolution limited by the laser beam spot size (finer than 10μm in diameter) with scan steps as small as 100μm or less

- DUT proximity: As close as 150μm

- Standoff distance (between field probe and mainframe box): Up to 50m

Why measure fields?

Measurement of electric and magnetic fields has numerous applications in different areas of RF technology. First and foremost, field maps shed light on the physical behavior of RF devices and systems. RF engineers typically use indirect and external measurement systems for high frequency characterization. For example, a network analyzer measures the port characteristics of a device. A spectrum analyzer captures the spectral contents of the signals at the input or output of your RF system. Antennas are traditionally characterized by their far-field radiation patterns. Such external measurements do not reveal much about how signals, fields and waves evolve, build up and propagate inside your device from one port to another, or out into the free space.

Just as an oscilloscope probe measures voltages and currents at various points of an electronic circuit, imagine if you could measure electric or magnetic fields at any point inside or around a distributed RF system without perturbing them! That’s what NeoScan exactly does for you.

What can I use the NeoScan system for?

The following are a few examples of how you can use the NeoScan system to measure electric fields in a variety of applications:

- High-resolution near-field scanning

- RF test & characterization

- Compact antenna range alternative

- RF circuit & device diagnostics

- Phase calibration of active phased arrays

- Real-time field detection

- EMC/EMI testing & certification

- Ultra-wideband pulse waveform probing

- High-power microwave system evaluation

- Field monitoring in medical devices and biological/saline environments

- Non-contact, non-invasive, remote field sensing & evaluation

- Model verification & validation (V&V)

The Electro-Optic Effect

The operation of the NeoScan system is based on the Pockels effect, which predicts the phase retardation and change of the polarization state of an optical beam in an electro-optic (EO) crystal due to an impinging electric field. This effect is observed in non-centrosymmetric crystals when an electric field directed along certain crystal axes causes a change in the indices of refraction encountered by a propagating optical beam. The electro-optic effect provides a means of modulating the phase or intensity of the optical radiation. It also makes it possible to detect the presence of an external electric field penetrating an EO crystal. A comparison of the polarization states of the optical beam before and after interacting with the crystal allows a determination of the amplitude and phase of the present RF electric field. Since the electro-optic sensing phenomenon relies on small displacements of the atomic crystal structure, the response time of the process is extremely short. This short response time makes it possible to measure high-frequency electric fields up to the terahertz regime.

The anisotropic nature of the EO probe tip allows accurate measurement of all the three components of the electric field with a high degree of polarization purity. The NeoScan system features both tangential and normal field probes. A normal EO probe is only sensitive to the electric field component parallel to the probe axis, whereas a tangential probe is sensitive to the electric field component perpendicular to the probe axis and parallel to the EO crystal orientation. Through precise synchronization of the optical and RF signal generation and processing systems, NeoScan is able to measure the relative phase of the electric fields of the device under test (DUT) very accurately.

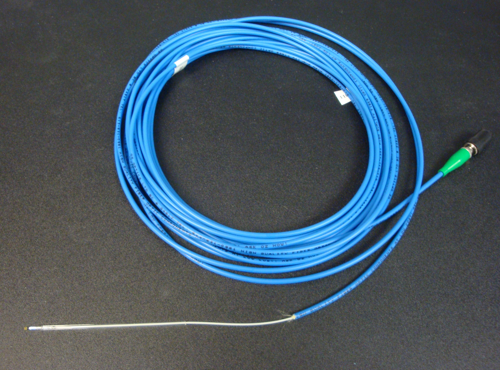

NeoScan Field Probes

A NeoScan EO field probe is composed of an optical fiber affixed with an EO crystal. A low-noise 1550nm laser is used as the optical beam source, which is delivered to the optical probe through a fiber-based optical mainframe system. The modulated beam in the crystal is reflected back into the fiber, and its intensity is linearly proportional to the strength of the external electric field at the probe tip location.

NeoScan field probes are connected to the optical mainframe using polarization maintaining (PM) fiber. The PM fiber plays a critical role in maintaining the integrity of the modulated field data. Our standard field probes come with fiber lengths of 10m, 20m and 50m, allowing large standoff distances.

A Brief History of NeoScan

The origins of electro-optic field mapping technique goes back to the research work conducted at the University of Michigan’s Radiation Laboratory and NASA Center of Excellence for Terahertz Space Technology during the 80s and 90s. The initial EO mapping systems used free-space optics and high-power pulsed lasers. During a 12-year period of intensive research and development (2002-2014), EMAG Technologies Inc. and its subsidiary Opteos Inc. received a large number of contracts from the US Department of Defense to transition this promising technology from laboratory setup to a reliable commercial product. The new third-generation NeoScan systems utilize compact low-power CW laser sources reduce both cost and size and provide a much higher level of reliability and measurement repeatability.

Related NeoScan Technology & Application Articles

- Yaghmazadeh, S. Schoenhardt, Arya Sarabandi, A. Sabet, K. Sabet, F. Safari, L. Alon, and G. Buzsáki, “In-vivo Measurement of Radio Frequency Electric Fields in Mice Brain,” to be published in Biosensors and Bioelectronics, vol 13, May 2023.

- Rao and K, Sarabandi, “A Near-Field-Based Gain and Pattern Measurement Technique for Probe-Fed Millimeter-Wave Antennas,” IEEE Antennas and Propagation Magazine, vol. 64, no. 65, pp. 91 – 100, 6 Dec. 2022.

- Rao and K, Sarabandi, “A Low-Profile Dual-Band Dual-Polarized Quasi-Endfire Phased Array for mmWave 5G Smartphones,” IIEEE Acces, vol. 10, pp. 38523 – 38533, 7 Apr. 2022.

- Amjadi, M. Rao and K. Sarabandi, “Wideband Near-Zone Radiative System for Exploring the Existence of Electromagnetic Emission from Biological Samples,” IEEE Transactions on Instrumentation and Measurement,” vol. 69, no. 10, pp. 8344 – 8351, October 2020.

- Deng , D. Liu, B. Yektakhah and K. Sarabandi, “Series-Fed Beam-Steerable Millimeter-Wave Antenna Design With Wide Spatial Coverage for 5G Mobile Terminals,” IEEE Trans. Antennas & Propagat., vol. 68, no. 5, pp. 3366 – 3376, May 2020.

- Dykeman, B. Marshall, D. Canterbury, C. Garner, R. Darragh, A. Sabet, “Comparison of Antenna Measurements Obtained Using an Electro-Optical Probe System to Conventional RF Methods,” Antenna Measurement Techniques Association Symposium (AMTA), San Diego, CA, 6-11 Oct. 2019

- Urbonas, K. Kim, F. Vanaverbeke, and P. H. Aaen, “An electro-optic pulsed NVNA load-pull system for distributed E-field measurements,” IEEE Transactions on Microwave Theory and Techniques, vol. 66, no. 6, pp. 2896-2903, June 2018.

- Sabet, R. Darragh, A. Sabet, K. Sarabandi, K. Jamil and S. Alhumaidi, “Characterization and diagnostics of active phased array modules using non-invasive electro-optic field probes with a CW laser source,” presented at the IEEE International Microwave Symposium, Honolulu, HI, Jun. 5-9, 2017.

- Sabet, K., Darragh, R., Sabet, A., Sarabandi, K., & Katehi, L. (2017). Using Electro-Optic Field Mapping for Design of Dual-Band Circularly Polarized Active Phased Arrays. IEEE 18th Wireless and Microwave Technology Conference (WAMICON). Cocoa Beach, FL, Apr. 24-25, 2017

- Sarabandi, J. Choi, A. Sabet and K. Sabet, “Pattern and gain characterization using nonintrusive very-near-field electro-optical measurements over arbitrary closed surfaces,” IEEE Trans. Antennas & Propagat., vol. 65, no. 2, pp. 489-497, Feb. 2017.

- Sabet, R. Darragh, A. Sabet and S. Hatch, “Characterization of dual-band circularly polarized active electronically scanned arrays (AESA) using electro-optic field probes,” presented at the 38th Annual Meeting and Symposium of the Antenna Measurement Techniques Association (AMTA), Austin, TX, Oct. 30 – Nov. 4, 2016.

- Yang, T. Marshall, M.l Forman, J. Hubert, L. Mirth, Z. Popovic, L.P. B. Katehi and J.F. Whitaker, “Active-amplifier-array diagnostics using high-resolution electrooptic field mapping,” IEEE Trans. Microwave Theory Tech., vol. 49, no. 5, pp. 849-857, May 2001.

- Yang, L.P. B. Katehi and J.F. Whitaker, “Electric field mapping system using an optical-fiber-based electrooptic probe,” IEEE Microwave & Wireless Comp. Lett., vol. 11, no. 4, pp. 164-166, April 2001.

- Yang, G. David, J-G Yook, I. Papapolymerou, L.P. B. Katehi and J.F. Whitaker, “Electrooptic mapping and finite-element modeling of the near-field pattern of a microstrip patch antenna,” IEEE Trans. Microwave Theory Tech., vol. 48, no. 2, pp. 288-294, Feb. 2000.

- Yang, G. David, S.V. Robertson, J.F. Whitaker and L.P. B. Katehi, “Electrooptic mapping of near-field distributions in integrated microwave circuits,” IEEE Trans. Microwave Theory Tech., vol. 46, no. 12, pp. 288-294, Dec. 1998.

Solving Challenging Problems through Innovation

The following videos showcase some of the exciting features and applications of the NeoScan family of field measurement systems:

A Brief Overview of the NeoScan System

Mapping the fields of a CPW thru line

Characterizing an S-band microstrip-fed patch antenna using NeoScan

Mapping the near-fields of a 64-element X-band patch antenna array

Characterizing an X-band slotted waveguide array

Scalable dual band active phased array AESA

Rotational Stage

Robot Arm

Phased Array+Anechoic Chamber

Pancake

Dipole Antenna

24GHzAntenna

Built to Your Exact Needs

EMAG Technologies Inc. offers a wide range of RF field probes, detection sensors and near-field scanning systems for direct measurement of electric and magnetic fields. Our products feature the state-of-the-art electro-optic and magneto-optic field sampling technologies and methodologies. Our turnkey NeoScan systems provide complete measurement solutions including the optical mainframes and probes, supporting electronics, precision translation stages of various sizes, control software, and post-processing tools for measured field data.

Our systems can be customized to meet your particular measurement needs with regard to sensitivity, spatial resolution, instantaneous bandwidth, test medium, ruggedized packaging requirements, etc. For example, beyond our standard 20GHz turnkey system, we can build custom NeoScan systems with higher operational bandwidths up to 100GHz. We can also build direct magnetic field measurement systems with magneto-optic field probes at lower frequency bands.

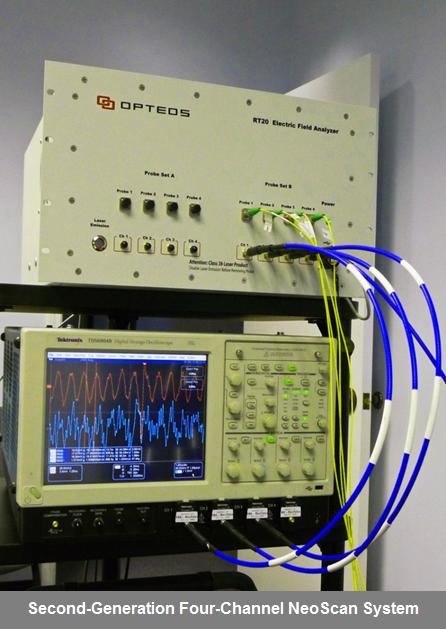

Many applications like antenna characterization require simultaneous measurement of two or more field components. We can build multi-channel NeoScan systems featuring fully independent channels. Each channel can have its own dedicated data acquisition back end, or multiple channels may share the same data acquisition back end using a built-in RF switch. The figures on the right show the latest 3rd generation three-channel NeoScan system with a three-axis EO probe as well as an older 2nd generation four-channel NeoScan system optimized for real-time high power pulse detection and tracking built by Opteos Inc., EMAG’s former subsidiary.

Please contact us to discuss your measurement requirements. Our engineers will recommend a system configuration that will best suit your measurement needs and budget. EMAG Technologies offers special academic discounts for educational/research use of the NeoScan system.